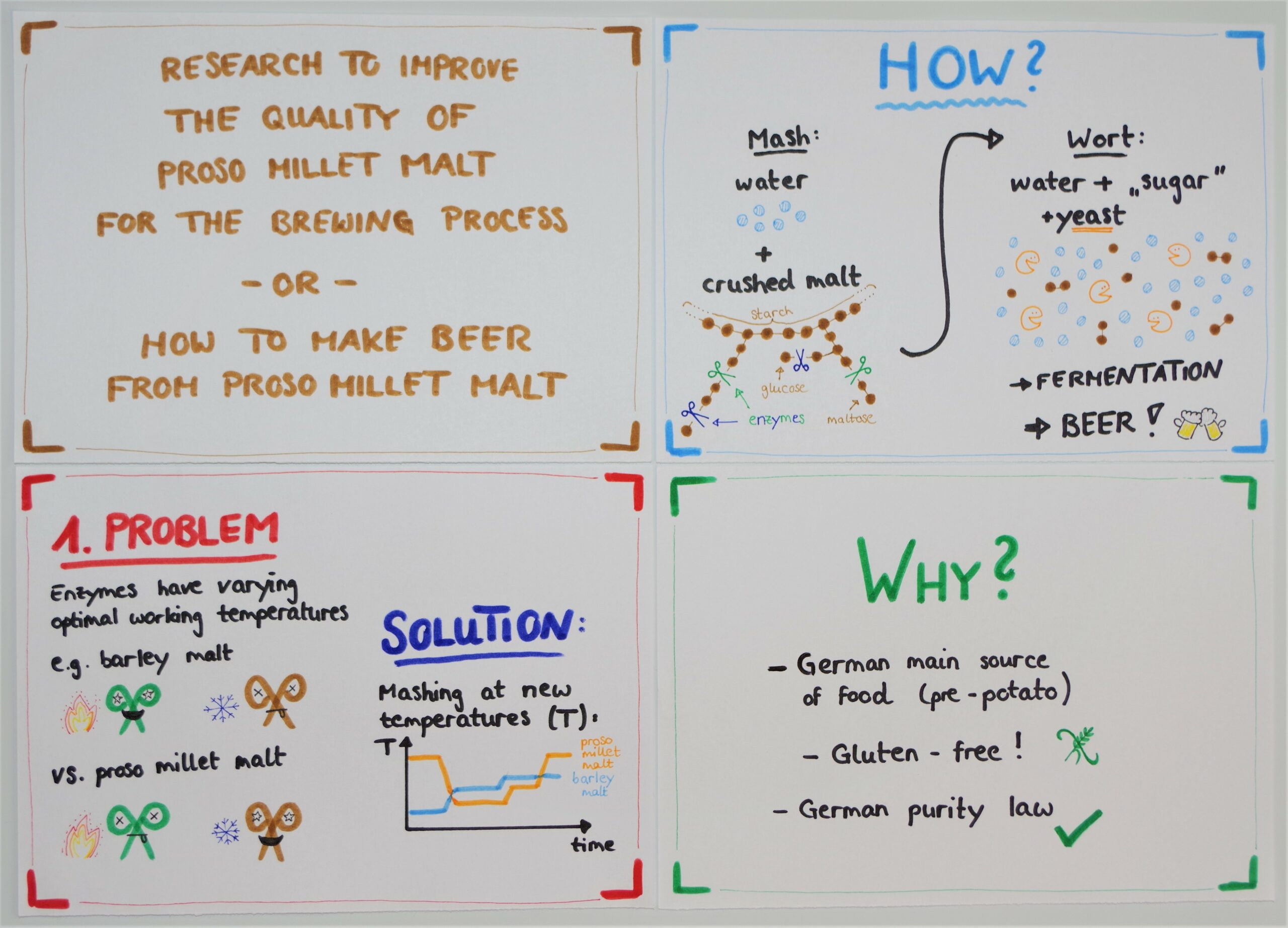

Research to improve the quality of proso millet malt for the brewing process OR How to make beer from proso millet malt

My CreaThesis starts with a general overwiew of the brewing process. The actual process is way more complex, but those are the most important steps. Crushed malt is mixed with water and held at several temperatures between round about 50 to 80 °C (depending on the specific procedure and the raw materials). During those rests, enzymes from the malt are degrading several ingredients of the malt, including starch and protein. The starch is broken down into fermentable sugars such as glucose and maltose, which will later be metabolized by the yeast. The mash is separated into solid particles and the remaining liquid which is called wort. The wort is boiled and cooled, and the yeast is added. The yeast ferments the sugars and produces mostly ethanol and carbon dioxide. Now comes the interesting part and simultaneously the problem I tried to tackle in my thesis: Brewers found out that you cannot just use any raw material in the process that is designed for using barley malt. Brewing with proso millet malt for example will lead to nearly no enzymatic degradation of the starch, which will of course lead to a poor fermentation performance and a bad beer. I found out that this is because the optimal working temperatures of enzymes from barley malt and from proso millet malt differ drastically – some from barley malt like it colder, while the same enzymes from proso millet malt like a higher temperature. So, my solution was to adapt the mashing procedure which is designed for barley malt to the temperatures I found in proso millet malt. And it worked! I tried the new procedure out and the results were very promising. But now you might wonder why this is important. We already have a raw material which is almost perfect for brewing beer – barley malt. The problem with barley is that it contains gluten, so people who are allergic to that cannot consume beer made from barley malt. Proso millet is gluten-free – and therefore perfect for brewing gluten-free beer. Also, it is a raw material that you can use in Germany, where the strict regulations of the German purity law apply.

Simplified Abstract

Since the number of celiac disease cases rises globally, the demand for gluten-free beers with proso millet malt as the main ingredient also increases. Yet the problem with proso millet malt is that the wort (= “beer before fermentation”) is lacking quality when being processed the usual way in the brewery. These low-quality worts cause major microbiological and technological problems throughout the whole production process. Therefore, the production of the wort, which is called mashing, needs to be adjusted. During the mashing crushed malt is mixed with water and this mixture is then heated to different temperatures (e.g. 50 to 78 °C for barley malt). There are several temperature rests during which the enzymes in the mash are degrading the malt ingredients (starch, proteins etc.). The most important enzymatic degradation is the breakdown of starch into fermentable sugars. It is very important that the rests are being held at special temperatures, since every enzyme has its optimal working temperature.

In my thesis I found out that the optimal working temperatures of proso millet malt enzymes differ strongly from the ones found in barley malt. Therefore, brewing with proso millet malt requires a mashing procedure especially designed for this special raw material. With my findings about the ideal malting conditions for proso millet and about the special enzyme characteristics of proso millet malt I designed such a mashing procedure. With this adapted process, producing a high-quality wort with proso millet malt was finally achieved. The satisfactory wort test results lead to the conclusion that proso millet is a suitable gluten-free raw material for the brewing process.

Name: Magdalena Bader